- Home

- About Us

- Products

- VentSaver Instructions

- SS Ventsaver Panel Matrix

- Contact

VentSaver Vent Guards Installation Instructions:

These installation guidelines are provided as assistance to installers with commercial and residental sites. VentSaver.com takes no responsibility for errors or omissions and cannot be held responsible for product installation.VentSaver FB-151 Installation Method |

|||

Mount VentSaver FB-151 in 3 Easy Steps: |

|||

| Recommended Tools: Cordless drill with 5/16" driver, tin snips, two 7/16" wrenches, caulk gun | |||

|

|||

| 1. Attach FIN to BASE ANGLE

Assemble with two 1/4" X 3/4" S.S. bolts. NOTE: In case of rib obstruction, base angle is reversible. |

2. Base Installation: Put sealant on bottom of base angle. Place Ventsaver centered behind pipe and fasten base to roof with the four 1 1/2" lag screws. | 3. Strap Installation: Put 1/4" X 3/4" bolt through the bent end of the strap. Install as illustrated in TOP VIEW. Cut off excess strap. For vent pipes cut pipe off 2" to 3" above the Ventsaver. | |

| Check all fasteners for tightness! | |||

VentSaver P-383 Installation Method |

|||

Mount VentSaver P-383 in 3 Easy Steps: |

|||

| Recommended Tools: Cordless drill with 5/16" driver, tin snips, two 7/16" wrenches, caulk gun | |||

|

|||

| 1. Attach FIN to BASE ANGLE

Assemble with two 1/4" X 3/4" S.S. bolts. NOTE: In case of rib obstruction, base angle is reversible. |

2.

Base Installation: Put sealant on bottom of base angle. Place cable over chimney

or vent with Ventsaver centered behind and close to pipe. Fasten base

to roof with

the four 1

1/2" lag

screws. Note: If unable to fit the cable over the top of the pipe, detach the cable eye by removing the nut. Wrap the cable around the pipe and reassemble tightly. |

3. Pull on cable end with pliers until snug.

Keep shoulder strap on the opposite side of teh pipe from the Ventsaver.

Tighten nut and bolt firmly. Trim Excess cable. Note: For smaller applications, cut and remove stainless steel shoulder strap attached to cable. |

|

| Check all fasteners for tightness! | |||

VentSaver HD Installation Method |

|||

Mount VentSaver HD in 4 Easy Steps: |

|||

| Recommended Tools: Cordless drill with 5/16" driver, tin snips, two 7/16" wrenches, caulk gun | |||

|

|||

1. Attach FIN to BASE ANGLE

|

2. Base Installation: Place cable over chimney

or vent with Ventsaver centered behind and close to pipe. Fasten base

to roof with

the four 1

1/2" lag

screws. |

||

3. Pull on cable end with pliers until snug.

Keep shoulder strap on the opposite side of teh pipe from the Ventsaver.

Tighten nut and bolt firmly. Trim Excess cable. |

4. Install Snow Diverter Wing Kit (Optional)

|

||

| Check all fasteners for tightness! | |||

Standing Seam Ventsaver Kit |

|||

|

This kit includes: (1) ¼" Adjustable Aluminum Plate – 19"

or 27" wide (1) 1/8" aluminum Ice Ramp w/ edging

strip (4) RCT universal fit standing seam

clamps (12) Tek screws – ¼" x 1" 3/8" hex head (12) Set screws for the clamps – 3/16"

hex/allen drive (4) 9/16" hex RCT top bolts with

stainless washers (1) 3/16" hex bit for set screw

tightening Ventsaver kit includes Fin, Base

Angle, (2) ¼" x ¾" s.s. bolts with (2) lock nuts, steel cable, 2 cable locks

with 5/16" nuts.

Tools Needed for Installation Safety Goggles and Gloves Wax or Lead Pencil to mark clamp

location Ratcheting Torque Wrench (capable of

reading in in/lbs) Tape Measure 9/16" Socket 7/16" Socket or wrench 3/8" Socket 1/8" Drill Bit Screw Gun or Impact Driver Adjustable Wrench Hand Grinder , Hacksaw, or Sawzall

with metal blade The SS VentSaver Kit is available in two sizes. Model 12-16 fits seams 12"

to 16" wide. This is the best option if

your seams are 16" or less in width in order to avoid excessive overhang.

Model 12-24 fits all seams

from 12" to 24" wide. This universal fit

bracket is best used with seams wider than 16", but has the ability to span

across two 12" wide seams if needed.

This is a good option for contractors that need a universal fit device

in stock. Installation Procedure Prior to installation, read and fully

understand all steps required for the SS Ventsaver bracket AND for the Ventsaver

device being attached to the pipe. 1.

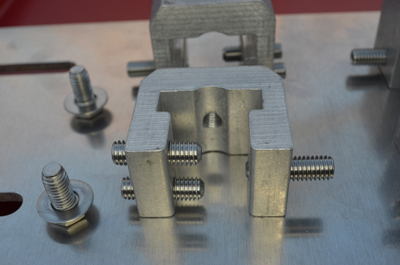

Load all 12 set

screws into the RCT clamps with the cupped tips pointing inwards and the female

hex end pointing outwards. Keep the

single set screw flush and the 2 adjacent set screws evenly spaced so that the

clamps install straight.

2.

Attach the 4

clamps to the Adjustable Aluminum Plate using the top bolts and washers. Clamps should be loose and able to slide side

to side in the bracket slots. Set onto seams just upslope of the pipe being

protected.

3.

Assemble the Fin to

the Angle Base as shown below with two ¼" x ¾" S.S bolts with 7/16" wrench or

socket.

4.

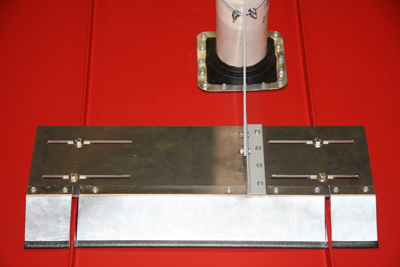

Once assembled,

set it on the Adjustable Aluminum Plate so it is centered with the pipe located

down slope and just touching the tip of the Fin. Move the Adjustable Aluminum Plate up the

seam until the Base Angle is properly positioned and flush with the edge of the

Plate closest to the pipe. Mark the (4)

holes in the Base Angle and the location of all 4 RCT clamps on the seam. Pre-drill 4 pilot holes, with a 1/8" drill

bit, using the holes in the Base Angle as a guide. Make sure not to drill thru the roof panels. A small block of wood

temporarily slid underneath the plate works well. Before

running the screws in the plate, make sure the Tek Screws will not touch the

roof panel when tightened. Fasten Base Angle to Adjustable Aluminum Plate using

(4) Tek Screws, 3/8" bit, and a screw gun.

5.

Remove the RCT top

bolts and set the Adjustable Aluminum Plate/Ventsaver assembly aside. Using a 3/16" bit and screw gun or ratchet,

attach the clamps to the seams and set to 90 IN/LBS with a torque wrench

capable of reading IN/LBS. Hold steady

downward pressure on the clamps to be sure they stay flat and centered on the seam. 6.

Position the Adjustable

Aluminum Plate/VentSaver assembly over the clamps and reinstall the top bolts

and washers. Torque the top bolts to 90

IN/LBS. Regardless of where the pipe

protrudes through the panel, the Adjustable Aluminum Plate is always centered

on the seams with an equal overhang on both sides.

7.

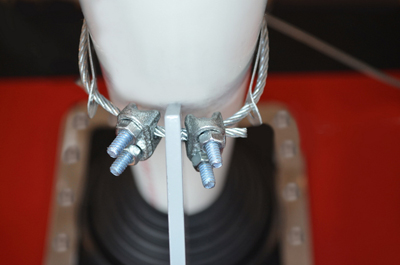

Run the cable thru

the hole in the top of the Fin, around the pipe and back through the hole. Install a cable lock on either side of the Fin

as shown, being sure to lock both cables in each cable lock. Vice grips can be used to hold the cable

together while you install the cable locks using 5/16" socket and screw gun. Trim off or tuck in the excess cable.

The Next Step is Essential!

8.

Installing the Ice

Ramp – This component is vital to keeping ice from sliding under the Adjustable

Aluminum Plate assembly and damaging the base of the pipe and/or the boot. The Ice Ramp needs to be custom cut to

properly fit your roof. A Sawzall with

metal blade, hand held angle grinder with cutoff blade, chop saw, or a simple

hacksaw can be used. Take precautions by using gloves and safety goggles to

protect yourself from injury while cutting and installing the Ice Ramp. Mark the location of the seams and be

sure to cut the center section about 1" narrower than the seams to avoid

scratching the panel. Fasten the center

piece of the Ice Ramp and 2 equal size end pieces to the upslope side of the Adjustable

Aluminum Plate, making sure the lip rests on the top of the plate. Use a 1/8" drill bit to pre-drill holes every

4" and fasten with Tek screws. Take

extra care to not drill through the plate into the panels. Use a temporary small

wood block, as previously done in step 4.

The Ice Ramp can be hand bent to allow for different seam heights. Be sure the edging is tightly in place and

that it rests on the panel when screwed down.

Some plate designs may require you to notch out for the end of the base

angle. This is easily done by

marking where the base angle will be and making two cuts 1" deep. Use pliers to

bend the cut section up, then use a hacksaw or grinder to remove the section.

The installation instructions above show

the pipe centered between the seams, but this isn't always the case. Regardless of where the pipe protrudes

between the seams, the Adjustable Plate is always centered on the seams with an

equal overhang on both sides. The Angle

Base can be fastened anywhere along the Adjustable Plate to accommodate the

location of the pipe. See Below for an

example of an off center pipe

|

|||

| Back to Top | |||

Warranty |

|||

| The following warranty is made in lieu of all other warranties expressed or implied. Recommendations for proper use of the product are based on tests believed to be reliable. Any goods proven to be defective due to materials will be replaced, or purchase price refunded, but in no event shall the manufacturer be responsible for damages in excess of the purchase price. User shall determine the suitability of the product for its intended use and assumes all risks of its use or handling. | |||